Download the complete article here

Introduction Financial considerations—namely, purchase price and operating costs—always figure in the selection of lighting products, but many other aspects also come into play, varying in importance depending on the application. LEDs have several unique attributes,

and it is critical to understand how they can be used advantageously.

Some considerations are dependent on product design, Building Technologies Program SOLID-STATE LIGHTING TECHNOLOGY FACT SHEET Image Credit: Cree

but others amount to using LEDs in appropriate situations. Some of the potentially favorable characteristics of LED sources compared

to traditional lamps include:

•

Directional light emission

•

Size and form factor

•

Resistance to mechanical failure (i.e., breaking)

•

Instant on at full output

•

Rapid on-off cycling capability without detrimental effects

•

Improved performance at cold temperatures

•

Dimming and control capability

•

Opportunity for color tuning

•

Minimal nonvisible radiation [e.g., ultraviolet (UV), infrared

(IR)]

•

Extended lifetime

LEDs are semiconductor devices that emit light through electroluminescence.

1 This basic fact is the foundation for many of the

advantages of LEDs, since it is different from traditional light sources. For example, incandescent lamps rely on a heated filament

to emit light, fluorescent lamps create light using a gas discharge

to excite phosphors, and high-intensity discharge (HID) lamps utilize an electric arc discharge. All of these traditional technologies require a glass bulb to contain essential gases and/or coatings.

In contrast to the large form factors of traditional lamps, LED lighting starts with a tiny chip (also called a die; most commonly about 1 mm2) comprised of layers of semiconducting material— the exact material determines the wavelength (color) of radiation that is emitted. At the next level are LED packages, which may contain one or more chips mounted on heat-conducting material and usually enclosed in a lens or encapsulant. The resulting device, typically less than 1 cm2, can then be used individually or in an array. Finally, LEDs are mounted on a circuit board and incorporated into a lighting fixture, attached to an architectural structure, or made to fit the form factor of a traditional lamp (or as it is colloquially known, a light bulb).

LED Package Design

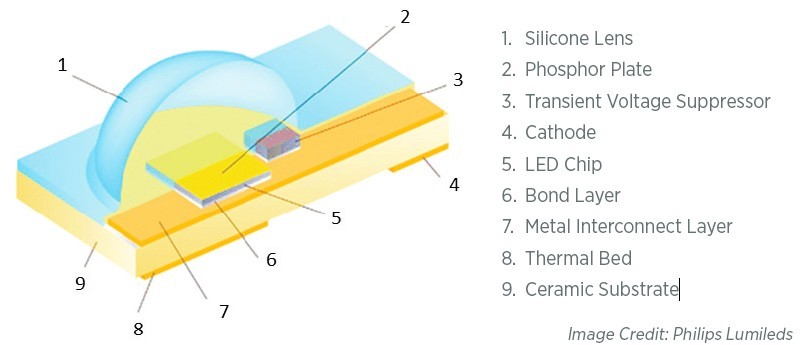

Although not all LED packages are built the same way, the basic components are often similar.

Besides the chip that is responsible for emitting

light, the various components are needed for thermal regulation, producing the desired spectrum, regulating electrical characteristics, or creating the appropriate distribution of light. All these components must work in harmony to produce a high-performance product. Many of the advantages of LEDs are derived from their unique physical attributes.

Directional Light Emission

Traditional light sources emit radiant energy in all directions. As such, an optical system—a lamp housing or a luminaire, with elements

such as a reflector or lens—is typically necessary to direct output in the desired direction. Because no optical system is perfectly

efficient, losses in efficacy result. Further, if the optical system

is not well designed (or is not present), light can be wasted, going in undesired directions.

Due to their physical characteristics and because they are mounted on a flat surface, LEDs emit light hemispherically, rather than spherically. For task lighting and other applications requiring directional lighting, this may increase the application effi cacy2 of the source. In contrast, with LEDs it is more diffi cult to obtain an omnidirectional distribution when it is desired, although innovative system designs now provide this capability.

Size and Form Factor

The small size, scalability of arrays, and directional light emission

of LEDs offer the potential for innovative, low profi le, or compact lighting products. This advantage can be aesthetic, but may also be functional. For example, reducing the depth of a luminaire may allow more room for ducts, conduit, or other building

systems in a ceiling cavity. It is even possible that the size of the ceiling plenum could be reduced. In contrast, the unique form factor of LEDs can be a disadvantage when competing with high-wattage HID sources. To match the lumen output, a very large array of LEDs is necessary.

Achieving small form factors requires careful design, specifi cally with regard to thermal management. Although LEDs used for general lighting do not emit infrared radiation (i.e., heat), they do generate thermal energy that must be moved away from the chip by a mass of material, which is called a heat sink. In order to produce

more light output, LEDs are often grouped into arrays, which dictate the use of additional heat-sinking material. Thus, although LED packages are small, matching the performance of small traditional lamps, such as MR16s, can be challenging.

Breakage Resistance

LEDs are largely impervious to vibration because they do not have filaments or glass enclosures. The life of standard incandescent

and discharge lamps may be reduced by vibration when operated in vehicular or industrial applications, although specialized

vibration-resistant lamps can help alleviate this problem. The inherent vibration resistance of LEDs may be beneficial in applications

such as transportation lighting (planes, trains, or automobiles),

lighting on and near industrial equipment, or exterior area and roadway lighting.

In addition to benefits during operation, LEDs offer increased resistance to breaking during transport, storage, handling, and installation. LED devices mounted on a circuit board are connected

with soldered leads that may be vulnerable to direct impact, but no more so than cell phones and other electronic devices. Because they do not contain any glass, LED fi xtures may be especially appropriate in applications with a high likelihood of lamp breakage, such as sports facilities or vandalism-prone areas, although they are not indestructible. LED durability may also be beneficial in applications where broken lamps present a hazard to occupants, such as children’s rooms, assisted living facilities, or food preparation areas.

Instant On

Most fluorescent lamps do not provide full brightness immediately

after being turned on. This is particularly relevant to amalgam

compact fluorescent lamps (CFLs), which can take three minutes or more to reach full light output. HID lamps have even longer warm up times, ranging from several minutes for metal halide to ten minutes or more for high-pressure sodium (HPS). HID lamps also have a restrike time delay; if turned off, they must be allowed to cool before turning on again, usually for 2 to 20 minutes, depending on the ballast. In contrast to traditional technologies, LEDs turn on at full brightness almost instantly, with no restrike delay. This advantage can be simply aesthetic or a user preference, but can also be beneficial for emergency egress or high-security situations. It is also especially important for vehicle brake lights—LED versions illuminate 170 to 200 milliseconds

faster than standard incandescent lamps, providing an estimated 19 feet of additional stopping distance at highway speeds (65 mph).3

Rapid Cycling

LEDs are impervious to the deleterious effects of on-off cycling. In fact, one method for dimming LEDs is to switch them on and

uorescent

lamps, the high starting voltage erodes the emitter material

coating the electrodes. Thus, lifetime is reduced when the rate of on-off cycles is increased. Due to the long warm up and restrike times, rapid cycling is not an option for HID lamps. Because of their operating characteristics, LEDs have an advantage

when used in conjunction with occupancy sensors or daylight

sensors that rely on on-off operation. Whereas the lifetime of fluorescent sources would diminish, there is no negative effect on LED lifetime.

Cold Temperature Operation

Cold temperatures present a challenge for fl uorescent lamps.4 In contrast, LED light output (and efficacy) increases as operating temperatures drop. This makes LEDs a natural fit for refrigerated and freezer cases, cold storage facilities, and many outdoor applications. In fact, CALiPER testing of an LED refrigerated case light measured 5% higher efficacy at -5 °C compared to operation at 25 °C.5 Conversely, operation of LEDs in hot environments or use of products with poor thermal management characteristics can lead to undesirable performance attributes ranging from reduced lumen output to premature failure.

Dimming Performance

Dimming is often a desirable operating characteristic, but most energy-efficient technologies have challenges that must be overcome

or mitigated. Many (but not all) LED products can be dimmed, although great care must be taken to ensure compatibility

between the different hardware devices (e.g., the driver and dimmer). Incompatible lamp and dimmer combinations may result in flicker, color shift, audible noise, premature lamp failure, very limited or no range of dimming, or failure to light. These problems may manifest themselves at full output and/or when dimmed. Furthermore, they are typically dependent on the number

of lamps connected to the dimmer. The best performing LEDs, when matched with a compatible dimmer, have better dimming performance than CFLs (limited range) or HID lighting (limited, if any, dimmability). However, there is a substantial performance

differential among LED products and for various LED-dimmer combinations.

Tunability

One of the most significant advantages of LEDs is the ability to mix chips of multiple types in a single product. For example, red, green, and blue (RGB) chips can be combined to make white light (and any color within their gamut), or two shades of white LEDs can be combined and adjusted independently to create light with varying color temperatures (i.e., warmer or cooler in appearance). Combining multiple fluorescent lamps also provides this capability,

but in practice, it is seldom utilized. Although the idea of

tunable light sources is not prevalent today, it is a tool that can be used to increase occupant satisfaction in a variety of settings, such as offices, hotels, restaurants, and homes. Thus, as LEDs become more widely used, the concept may see increased recognition

and application.

In addition to color customization, the output of LEDs can also be altered over the course of their lifetime. In this manner, it is possible

to prevent color shift and/or greatly reduce lumen depreciation.

Eliminating lumen depreciation is particularly advantageous because it would allow for the removal of lamp lumen depreciation

from design calculations, reducing initial over-lighting. This technology is not currently in widespread use, but as the equipment

becomes less expensive, the potential advantage may be realized.

No Infrared or Ultraviolet Emissions

Ultraviolet and infrared radiation bookend the spectrum of visible light, but do not contribute to humans’ ability to see. Ultraviolet radiation can damage artwork, artifacts, and fabrics, as well as causing skin and eye burns. Similarly, excessive infrared radiation

from lighting presents a burn hazard to people and materials. With traditional sources, ultraviolet and infrared emissions are either necessary to generate visible light (e.g., fl uorescent lamps) or simply an unavoidable component. The consequences of these undesirable emissions include reduced efficacy and/or the necessity

of providing additional safeguards. For example, the infrared radiation generated by incandescent lamps accounts for more than 90% of the power they draw. Metal halide lamps require an ultraviolet-blocking outer bulb (or to be operated in an enclosed

fixture) due to the significant level of ultraviolet radiation emitted is essential to evaluate appropriate data and, if necessary, conduct from the inner arc tube. a physical evaluation of a mock-up.

Based on how they generate radiant energy, LEDs chosen for general

lighting applications do not emit much (if any) ultraviolet or infrared radiation. This helps boost efficacy and reduces the potential for undesirable consequences.

Extended Lifetime

The rated lifetime of LED products is at least comparable to other high-efficacy lighting products, if not better, and for many specific product types, LEDs have the highest rated lifetime. This attribute can be especially important where access is difficult

or where maintenance costs are high. In fact, several U.S. Department of Energy GATEWAY demonstrations have revealed that maintenance savings, as opposed to energy savings,

are the primary factor in determining the payback period for an LED product.

Conclusion

The LED product market continues to grow rapidly. In many applications, today’s high-quality LEDs can outperform traditional

technologies when evaluated with conventional metrics including efficacy, color quality, and operating cost. However, LED products have significant variation in performance from one product to the next. Thus, generalized comparisons are often misrepresentative.

The attributes discussed in this fact sheet are predominantly a result of the physical characteristics of LEDs, and may not show up in a catalog or on a specification sheet. It is critical to understand

the specific needs of a given application in order to select the most appropriate technology. Considered holistically, the best option may not always be the most efficacious. No matter how much energy can be saved, a product that does not meet the performance

requirements is not a good choice.